Deodorizing filter

· Technology · Technical · Deodorizing filter

What is Activated Carbon ?

Activated carbon is widely used as an adsorbent together with zeolite, alumina, silica gel, somerite, and synthetic adsorbents.

Among them, in terms of adsorption capacity and economy, activated carbon is the best material as an adsorbent.

The usefulness of activated carbon adsorbent technology has been proven for a long time, and various technologies have been developed mainly in developed countries. In the case of Korea, on activated carbon, research on activated

carbon began to progress rapidly in the 1990s.

Definition

Activated carbon is a collection of amorphous carbon consisting of innumerable well-developed Mirco Pores, Tracnmental Pores, and Macro Pores, and the micropores are composed of innumerable interconnected passages and have a large internal surface area.

This surface area determines the suitability of the pore size according to the relative molecular size and the adsorption capacity, which is the life of activated carbon, and 1g of activated carbon has a very large surface area of 1,000-1,600㎡, and the pore distribution is 150,000Å, mainly in the pore structure of 10Å

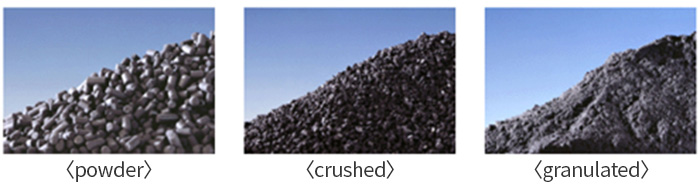

Classification according to physical shape

| classification | Shape |

|---|---|

| Assembly (molding) activated carbon | shape and size irregularities |

| Assembly (molding) activated carbon | Various molding shapes and sizes by adding binders |

| powdered coal | Regulate the density distribution |

Classification according to raw material

| classification | Shape | Shape |

|---|---|---|

| plant-based activated carbon | Sawdust, wood, coconut palm, etc. | Regeneration recovery rate (80 ~ 85%) |

| Coal-based activated carbon | peat, lignite, bituminous coal, etc. | Regeneration recovery rate (80 ~ 85%) |

| Petroleum Activated Carbon | Petroleum residue, annular slush, etc. | |

| Other | Pulp waste liquid, synthetic resin waste liquid |

Characteristics of Activated Carbon

- It has high adsorption capacity for organic molecules

- The effective surface area is very wide due to well-developed micropores (more than 1000㎡/1g)

- High physical and mechanical strength

- Excellent heat resistance and low loss during regeneration

- It is suitable for advanced filtration (purification) facilities due to its low pollen and high purity.